ALUMINIUM 2018 in Dusseldorf

Explore the value chain of aluminium and its applications in automotive, construction, aviation, and more. Join us at ALUMINUM 2018 in Düsseldorf.

ALUMINIUM 2018 in Düsseldorf

From 9 by 11 October 2018 year next Congress will be held in Düsseldorf ALUMINUM 2018.

See also: ALUMINIUM 2016

As it was in 2016 year

From 29 November 1 December 2016 of the year, in Düsseldorf, Germany passed the most important event of the aluminum industry – a global ALUMINIUM International Exhibition 2016.

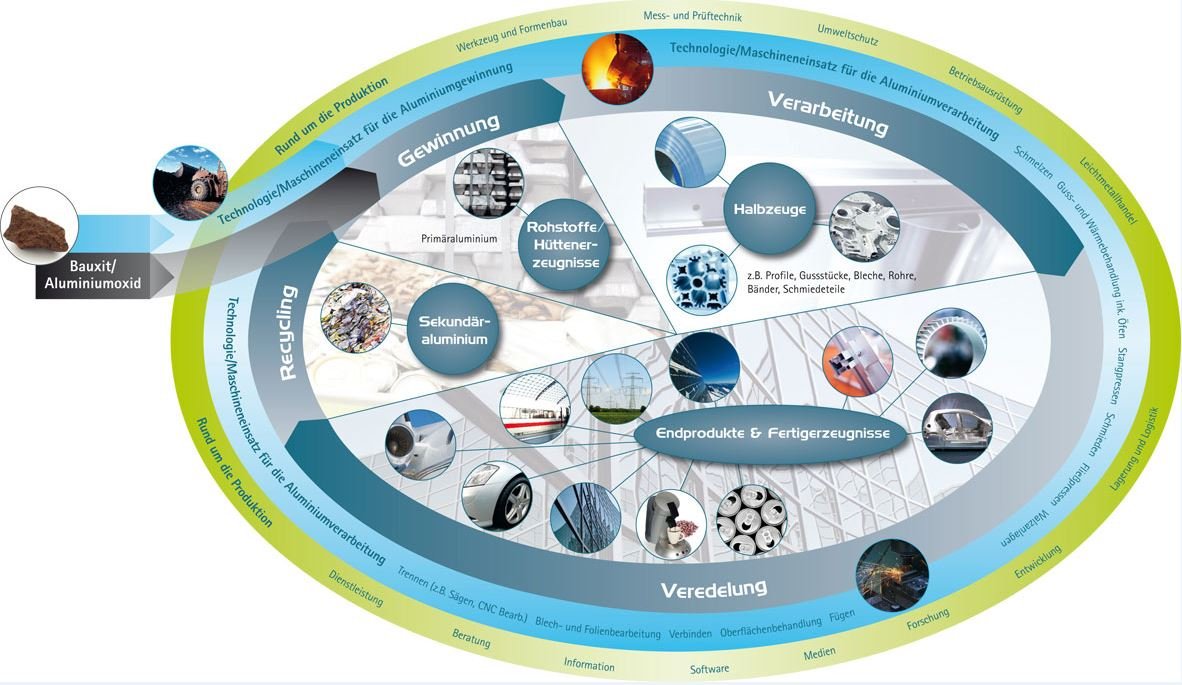

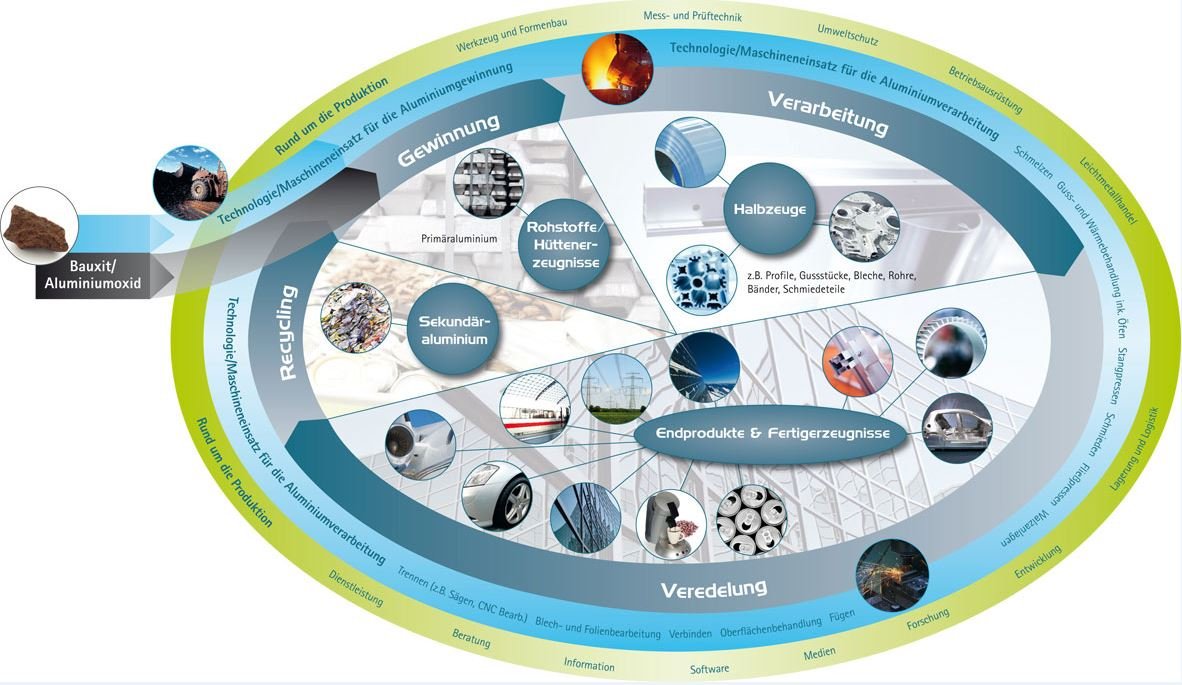

The whole value chain for aluminum

On the exhibition-fair Aluminum in Düsseldorf participated more 900 companies, enormous, large, medium and small. They covered the entire value chain for aluminum, from global bauxite mining and primary aluminum smelting to private operations, such as, Aluminum consulting and journalism. It means, that aluminum provides inspiration for creativity and hundreds of thousands of jobs, or even millions of people around the world.

The value chain for aluminium

The value chain for aluminium

Aluminum in finished products

A good half of this value chain occupies the use of aluminum in industries, who produce finished products:

- automotive industry;

- construction;

- aviation and space;

- cars, aggregates and consumer goods;

- transport;

- product packaging.

Below is an overview of aluminum used in each of these industries.

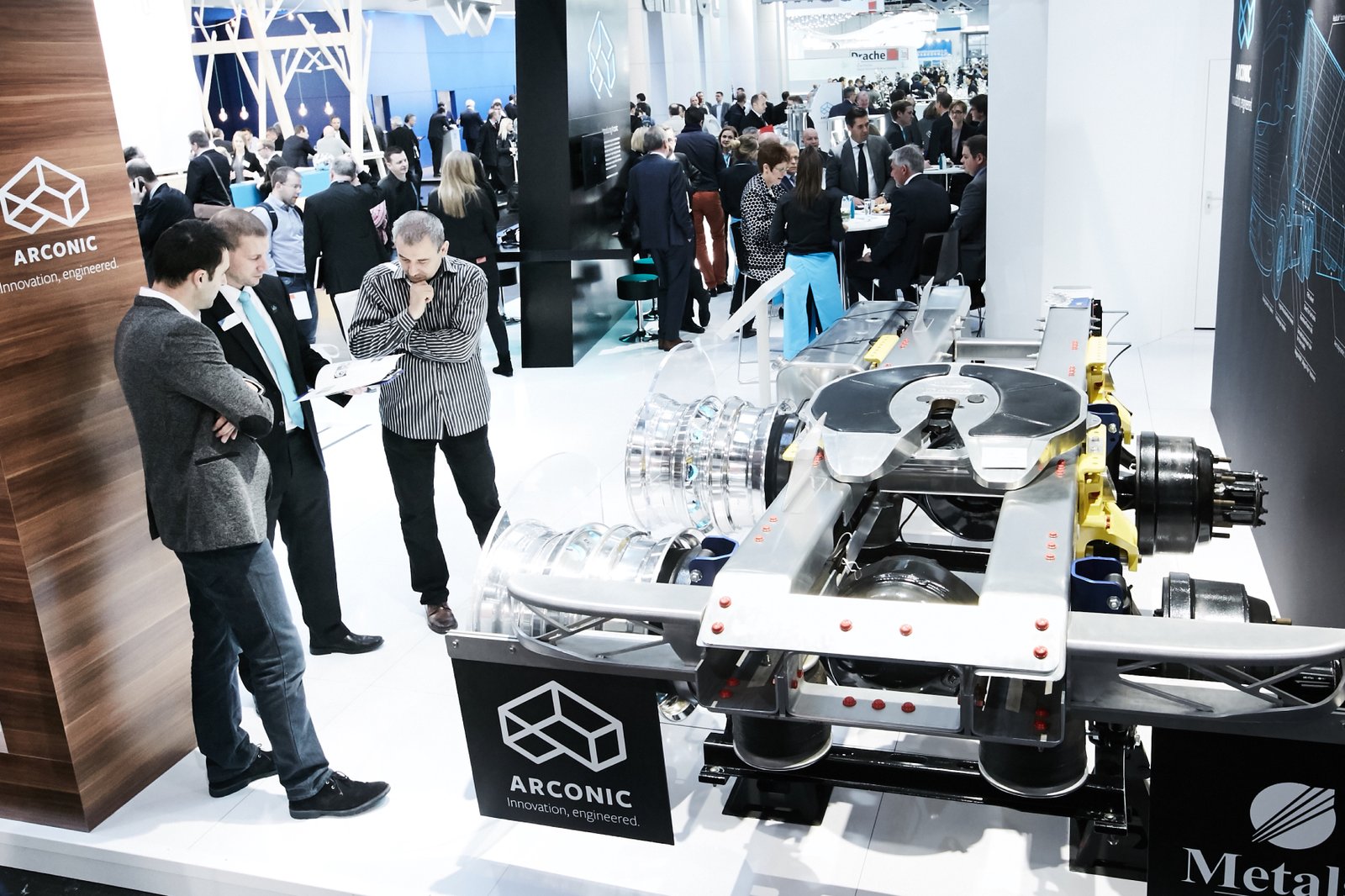

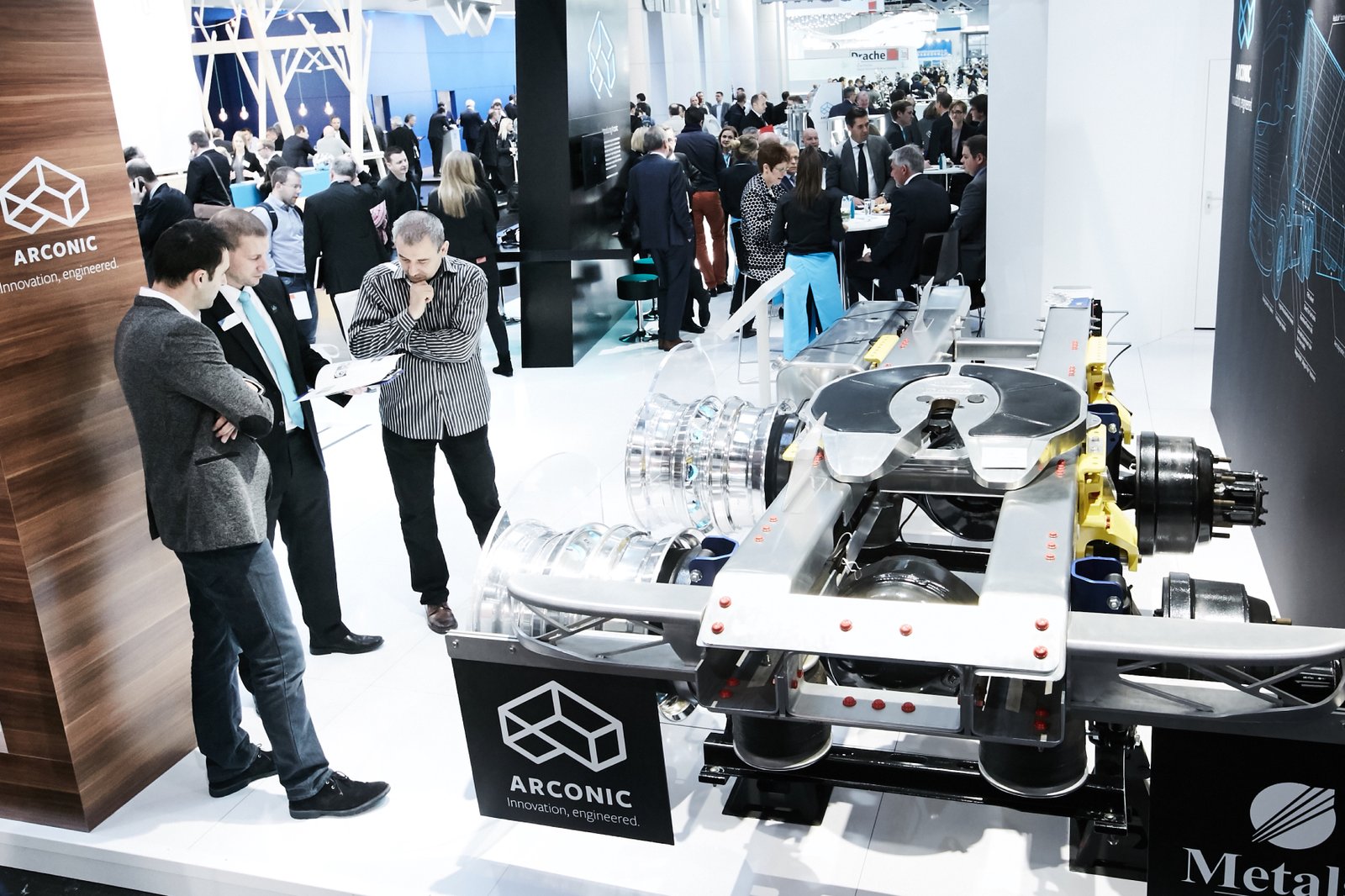

Automotive: the most important market

Modern megatrend towards lightweight construction in vehicles is a source of constant growth of aluminum use in cars. Aluminum in cars is becoming more and more – in engines, housing, bearing elements and chassis.

This trend is better seen in numbers – the mass of aluminum per car is constantly growing:

- sixty years ago, the car had 19 kilograms of aluminium

- from 1990 to 2013 , the proportion of aluminum in the car grew from 50 to 140 kilograms

- to 2020 the proportion of aluminum around 160-180 kg through the use of aluminum not only expensive, but in the mass car models

Aluminium car at Aluminium 2018 in Dusseldorf

Aluminum in construction: not only facades

The construction industry worldwide increasingly rely on aluminum as a building material. Small weight and high strength aluminum find application in the lung structures and facade supporting structures of bridges

In cooperation with glass aluminum sets the trends in modern architecture. aluminum is used, to create architectural masterpieces, which exhibit excellent insulation against the cold, heat and noise, a variety of colors the outer surface of buildings. Aluminum profiles give designers the possibility to implement the most unexpected technical solutions for facades, doors and windows and the successful implementation of their worldwide.

For many years, aluminum is used, to create a new design phenomenon in the internal environment of buildings. From high-quality furniture to the familiar things of daily aluminum really is a trendsetter of modern design trends.

Aluminum garden from RUSAL at Aluminium 2018 in Dusseldorf

Aerospace industry: technologies with a future

Weight reduction is a key element in the design of aircraft. All efforts are aimed at reducing aircraft fuel consumption and carbon dioxide emissions. Aluminum remains the most important material plane.

However, more light metals replaced plastics based carbon fiber. Nonetheless, aluminum industry has a solid reputation as a reliable partner for aircraft manufacturers. First of all, as a source of great potential for innovation. Moreover, proizodstvo mass parts of carbon fiber is not the most expensive affair. In a competitive aluminum industry must work even harder. Therefore, a few years ago, aluminum producers have focused on composite materials.

Aerospace – this is not the market, which is growing due to expansion of mass production. Therefore, the new technical findings on the results of scientific research are the main source of growth. Today need, so it’s new ideas, which could play a role in the future, including on the ground.

Aluminum for space and aviation at Aluminium 2018 in Dusseldorf

Office, home, leisure and sports: even more aluminum

By alloying in other elements, for example, zinc, copper, silicon or magnesium, Aluminum becomes capable vomprinimat different types of stress, which occur in the machines, units and products. The point of metallurgists – to create appropriate aluminum alloys, which have the desired characteristics.

In addition to its light weight aluminum has other important properties, for which it is appreciated by development engineers:

- chemical resistance,

- a variety of surface finishes,

- high conductivity of heat and electricity,

- high strength,

- molding complex shapes, rolling, forging, forging or extrusion.

In recent years, these techniques give aluminum a predetermined shape a serious competitor – 3D-printing, special, for prototypes and small series products. Experts predict 3D-printing is a huge market. Little of, that this technique can be cheaper to manufacture individual products. It can create components with structural characteristics, which can not be obtained by traditional technology.

Aluminium dress at Aluminium 2018 in Dusseldorf

Transport engineering: even easier, more effectively

In buses, trucks, wagons or ships, on the ground or on the water – all aluminum gives ideas for today, environmentally friendly and cost-effective solutions in today’s transport.

The aluminum rail vehicles not only saves energy due to its low weight, but also help the trains reach higher speeds. Four out of five passenger cars in Western Europe are now made of aluminum.

Modern ships have to be quick, manervennymi, light and at the same time, strong and durable. All of these properties they are given aluminum alloys, which are used in the modern shipbuilding industry. Modern aluminum materials provide all, require that ships, yachts and boats: durability, resistance to corrosion, including, in seawater, and , water-, The Air- and pogodonepronitsaemost.

In public transport, for example, buses and trams, The use of aluminum also gives its rewards. Modern city buses with aluminum body several hundred kilograms lighter, conventional buses.

Aluminium transport at Aluminium 2018 in Dusseldorf

Packing: efficient and impervious

Functionality, usability and creative design – these are just some facets of modern packaging industry. Aluminum is one of the most versatile and efficient packaging materials, either alone, or in combination with other materials.

Aluminum provides reliable protection products, but, what is more important for its success in the market – is its unparalleled comfort. Aluminum cans and include aerosol cans. These aerosol cans provide the desired dosage thanks to the integrated spray system.

Recycling of aluminum packaging in Germany is gaining momentum: from more than, than one hundred thousand tons of aluminum, which is used in packaging, the smelter receives about 90 %. For beer cans even higher result – about 96 %.

It’s time to buy airline tickets

October 2018 – it will soon. It’s time to buy airline tickets, while they’re cheap!)