Aluminium applications

Discover the diverse applications of aluminium in industries like construction, packaging, and electrical engineering. Find out how this versatile material is used in everyday products and machinery.

Aluminium consumption

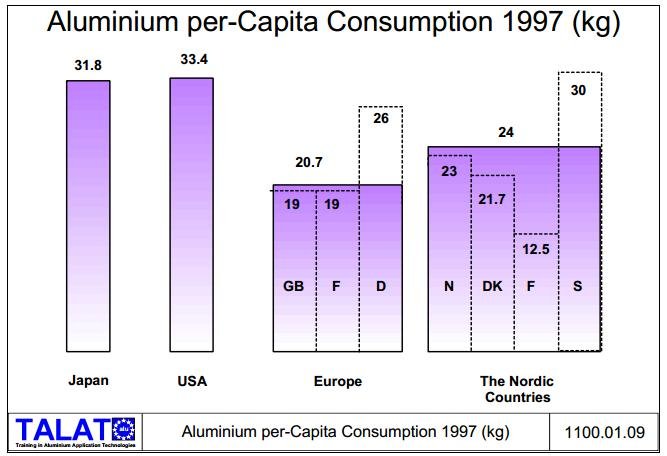

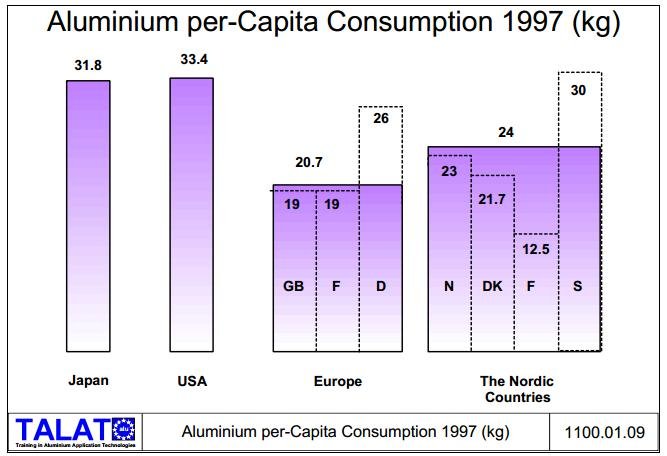

Per capita consumption of aluminium in the developed world as of 1997 year shown in the figure below.

Figure 1 – Aluminium consumption per capita in Japan, USA and Europe (1997) [4]

Figure 1 – Aluminium consumption per capita in Japan, USA and Europe (1997) [4]

The main industries, which are actively used aluminum, are:

- Construction

- packaging products

- Electrical industry

- transportation engineering

- Manufacture of machinery and equipment

- Production of goods for everyday life

- Powder metallurgy

- Killed steel in the steel industry

Aluminium applications in construction

Aluminum windows and facades

The main aluminum alloys, which find use in the construction industry, are alloys 6063 и 6060, and Alloy 6082 (in Europe) and alloy 6061 (in North America). They have a fairly high strength (6082 and 6061 – to 400 MPa) and good corrosion resistance.

Figure 3 – Window aluminium extruded profiles with thermal break (6060/6063 alloys)

Figure 4 – Aluminium curtain wall

Figure 4 – Aluminium curtain wall

The aluminum roof and aluminum cladding of buildings

Decorative and protective profiled facing materials are frequently made from rolled aluminum sheets. Various kinds of decorative and protective coatings make them ideal materials for use as a roofing material.

Figure 5 – Aluminium roofing

Aluminium applications in transport

Aluminium in cars

In 2008 the average weight of the aluminium in passenger cars in Europe was about 118 kg and continue to increase.

Various components and parts of cars are (in kilograms per car):

- engine cylinder blocks: 40,3

- transmission: 16,3

- chassis, suspension and control: 12,5

- wheel: 17,7

- heat exchanger: 12,3

- brakes: 3,7

- body: 6,8

- heat shields: 1,4

- bumpers: 2,8

- other components: 3,9.

Figure 6 – An aluminium cylinder block

Figure 7 – Aluminum car wheel

Figure 8 – Aluminium car body

Aluminum alloys for trucks

Figure 9 – Aluminium alloys for tank trucks [5]

Figure 10 – Aluminium alloys for dump truck bodies [5]

Figure 11 – Aluminium alloys for car vans [5]

Figure 12 – Aluminium alloys for truck chassis [5]

Figure 12 – Aluminium alloys for truck chassis [5]

Aluminium in railway car building

Figure 13 – Aluminum carriage of urban rail transport [7]

Figure 14 – Freight aluminum wagon for coal transportation [7]

Figure 14 – Freight aluminum wagon for coal transportation [7]

Aluminum in shipbuilding

Figure 15 – Aluminum patrol boat

Figure 15 – Aluminum patrol boat

Figure 16 – Cruise ship with aluminum superstructure [5]

Figure 16 – Cruise ship with aluminum superstructure [5]

Aluminium alloys for aircraft

- The first airplane the Wright brothers in 1903 was mostly wooden and had aluminium engine.

- Among aluminium alloys, which are used in aircraft dominated high strength wrought alloys, such as, 2024 alloy (containing copper and magnesium) and 7075 alloy (containing magnesium, zinc and a little copper). Most of the aluminum alloys, which are used in aircraft, and their non-welded are combined in mainly rivets.

- The figures below show the use of the series 2xxx alloys for airplane fuselage manufacture and 7xxx series alloys for wings.

(a)

(б)

Figure 17 – Application of aluminum alloys in aircraft construction:

a – 7xxx series alloys for fuselage and

b – 2xxx series alloys for wings [2]

Armour aluminium

There are several benefits that make aluminum an material in many kinds of armor:

- Aluminum has light (about one third that of steel).

- Aluminium offers a high strength-to-weight ratio.

- Ballistic performance must be balanced with light weight for vehicles that need to be transported by air, such as troop carriers.

- High corrosion resistance.

Aluminium applications in space technologies

- The first, who understood the enormous potential of aluminium for space, was a great writer Jules Verne. In his novel “Journey to the Moon” from back in the 1865 year a detailed description of a rocket made of aluminium.

Aluminium alloys for spacecraft

- Sputnik, which was launched in October 1957, was made of aluminum-magnesium alloy with magnesium content about 6 %.

- Aluminium-magnesium alloys remain the primary material for the manufacture of shells missiles.

- In the inner compartments missiles used duralumin and aluminium alloys.

Figure 18 – The first artificial space object is Soviet Sputnik

- In the last decades of the 20th century in the spacecraft began to use aluminum-lithium alloys.

- Lithium density is only 0,533 g / cm3 . It is lighter than water.

- Lithium additives in an amount up to 2,5 % reduce the density of aluminum alloy , as well as improve its modulus of elasticity.

- 8090 alloy has a density 10 % below, and modulus of elasticity 11 % higher, than the popular alloys in aircraft 2024 и 2014.

- Figure 19 shows the wheel of Mars rover Curiosity made of 7075 aluminium alloy.

Figure 19 – Wheel rover Curiosity aluminum alloy 7075-T7351 [7]

Aluminum is also used as a binder in composites, which is now also used in space technology (Figure 20).

Figure 20 – Borщт-aluminium composite (40 % boron fibers)

Figure 20 – Borщт-aluminium composite (40 % boron fibers)

Aluminшum powder – propellant component

- The high chemical activity of aluminum makes it possible to use it as a rocket fuel for solid-fuel boosters in the space launch system (SLS) being developed by NASA..

- The rocket boosters aluminum powder and perchlorate of ammonia are connected together using a special binder. This mixture, similar to the material eraser, then placed in a steel case [3].

- When this mixture illuminates, perchlorate oxygen from ammonia coupled with the aluminum to form aluminum oxide, aluminum chloride, water vapor and nitrogen gas, as well as with the release of huge amounts of energy.

Aluminium packing

- Rolled aluminшum foil – used in packaging of dry and liquid products.

- Aluminum packaging accompanies us throughout our lives – this is, for example, aluminum cans and bottles, foil packaging in food and medicine.

- Aluminum has a low density, compatibility with food and drink and attractive appearance.

- This makes it an ideal material for various types of packaging.

Aluminium wires and cables

The high electrical conductivity of the aluminum series of stamps 1000, as well as aluminum alloys series 8000, It makes them very suitable for electrical conductors. Aluminum conductors are used in the following cases:

- distribution electrical substations;

- power systems of high-rise buildings;

- high-voltage power lines;

- most underground power lines;

- Power cables for industrial applications.

Most of the aluminum in the electrical industry is used in the form of cables (8 of 13 %). However, it is used also in the form of electric buses for equipment with high current, as well as for electricity supply of large buildings. Moreover, cables for industrial, commercial and residential buildings may contain many insulated conductors, are placed in a common protective aluminum sleeve.

Heating and ventilation systems

Aluminium alloys og 3000, 5000 and 6000 series have good thermal conductivity. In combination with high strength, these alloys are good choices for use in heating and ventilation systems. These systems include the following components, in which aluminum alloys are used:

- compressors;

- condensers / evaporators;

- expansion valves;

- fans;

- tubes.

Consumer goods

Aluminшum in large quantities used in the manufacture of various components, parts and casings of many consumer products, that surround our lives – household goods, for example, refrigerators, morozylnykov, dishwashers. Refrigerators and freezers comprise chillers, that, as mentioned above, also contain a significant amount of aluminum. Important properties of aluminum for consumer products are:

- aesthetic properties;

- corrosion resistance;

- strength;

- high thermal conductivity (for refrigeration units).

Medical equipment and tools

Anodized aluminum is widely used for products and parts in the medical and dental equipment, including:

- Interior finish wards and medical offices

- Instruments, that can withstand regular sterilization in an autoclave

- hospital beds, stretchers, wheelchairs and other means for moving patients

- Equipment for medical oxygen

- Dental equipment and instruments

- X-ray machines

- Dialysis equipment.

Powder metallurgy

Powder metallurgy – a process, which allows the product as a complex, and quartered form with minimal dimensional tolerances, thus eliminating the subsequent machining.

Steel deoxidation

- To remove oxygen from the molten steel to the melt is added the so-called scavengers. As a deoxidizer often used aluminum, as well as manganese and ferrosilicon.

- Typically, aluminum is added to the molten steel in the form of a 10-kilogram bars. For one ton of steel deoxidation requires about one kilogram of aluminum.

Sources:

- WellMet, University of Cambridge, July 2010

- Lightweight Materials—Understanding the Basics /ed. F.C. Campbell – ASM International, 2012

- https://blogs.nasa.gov/Rocketology/tag/aluminum/

- TALAT 1100.01

- Aluminium in Commercial Vehicle – European Aluminium Association – 2011

- TALAT 3710

- https://vibrationdata.wordpress.com/2014/10/31/mars-curiosity-rover-wheels-low-cycle-fatigue-cracks/