Anode hangers

Anode hangers

Anode hangers are devices for supplying anodized aluminum products of the electric current. To ensure reliable continuous supply of electric current, anode hangers must perform, at least, three important requirements [2]:

- Hold the product firmly when moving it from bath to bath and when immersed in solutions with very strong mixing with compressed air

- To provide electrical contact for each product, which will reliably conduct sufficient electrical current from the rectifier to this product

- Ensure effective drainage products, preclude the formation of “pockets”, in which residues will accumulate working solutions and wash water

Aluminium anodizing princple

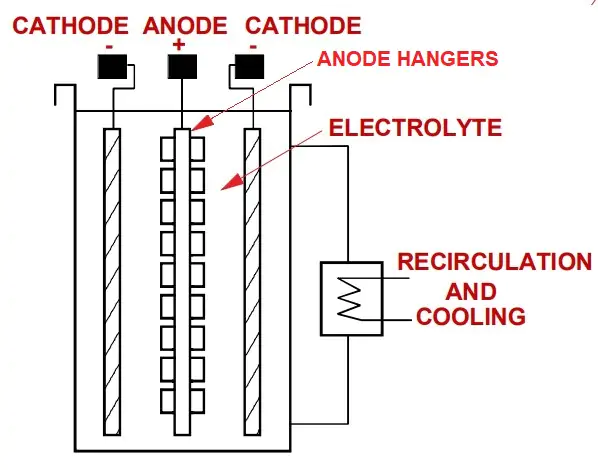

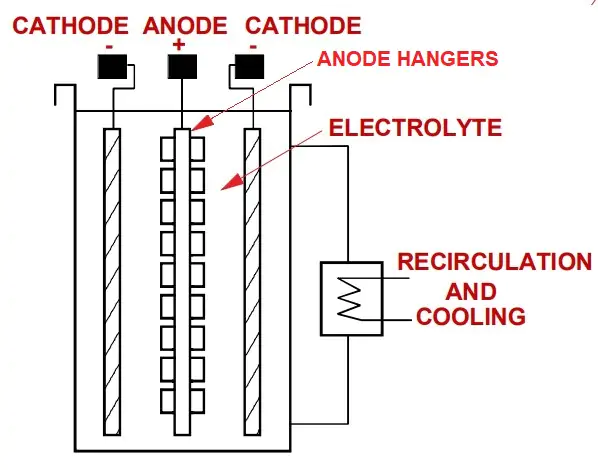

Anodizing aluminum products, for example, aluminum profiles, occurs by immersing it in a bath with an acid solution (usually, sulfuric) and connecting them to the positive pole of a direct electric current source. In this case the negative pole of a direct electric current is connected to the cathodes, which are located in the same bath (figure 1).

Figure 1 – Aluminium anodizing bath [1]

Figure 1 – Aluminium anodizing bath [1]

Sulphate aluminium anodizing

Depending on the type of acid, its concentration, temperature and electrical parameters as a result of this process produces the anodic coating with different properties. Most aluminum products are anodized at room temperature (20 °C) in a sulfuric acid solution (200 g / l) at an electric voltage 10-20 In. In the anodizing process on the surface of aluminum articles constant current density should be provided in a given interval values, depending on the thickness of the anodic coating. For , for example, to a predetermined thickness 20 microns the optimal current density range according to the standard of from Qualanod 1,4 to 2,0 A / dm2 [2].

Anode hangers for aluminium profiles

For different shapes and sizes of aluminum products using various types of anode batches of. Long sample anodizing aluminum profiles comprise vertical rods, are directly fixed to the anode beam. Aluminum profiles are attached to these rods by means of spring clips, clamps, wire or other methods. The anode bar is a massive aluminum profile, one of the ends of which, using a powerful pneumatic clamp (contactor), is connected to the DC busbars. To the anode rods using various accessories (clamps, spring rings, aluminum wire), anodized aluminum profiles are attached (figure 3). Popular clips of type “crocodile” are shown in Figure 2.

Figure 2 – “Crocodile” fast clamps for fixing aluminum profiles to anode hangers [3]

Figure 3 – A clamp for fixing aluminium profile to anode hanger [3]

Figure 3 – A clamp for fixing aluminium profile to anode hanger [3]

Titanium hangers for aluminum parts

For small anodizing aluminum products using various types of anode batches of, usually from titanium alloys, which are fixed directly to the anode beam (Figure 5). For aluminum products, these sample used different kind of spring device, for example, such, shown in Figure 6.

Figure 4 – Titanium anode hanger for anodizing aluminium parts [4]

Figure 5 – An example of fastening parts on a titanium anode hanger [4]

Figure 5 – An example of fastening parts on a titanium anode hanger [4]

Anode hangers design

Design factors for anode hangers

When designing anode weights, the following factors are taken into account:

- Compatible with the working solution

- Given current density, to be supplied to the product

- Easy to install products to sample weights and their removal from the test portions

- The presence on the product places for reliable contact points, which will provide a uniform anodic coating

- Location trace the point of contact to the ground, which are acceptable for the customer

- Location products at the hitch should not be too tight, so as not to cause local overheating of their, and the shading of some other products

- Economically acceptable cost

Durable fastening articles to anode hangers

Providing reliable continuous electrical contact with the product lifting, It is very important for forming on its surface a uniform anodic coating. Fixed on hinges, aluminum products have to go through all the technological bath without weakening the electrical contact, including, those baths, in which the solution vigorously stirred compressed air.

Drainage and gas pockets

When assigning method attaching each new product should be thoroughly checked, such that when attaching provides good drainage of liquids from the article, as well as the, that excluded the possibility of formation of so-called gas pockets. These pockets may collect hydrogen, which is released in the process of anodizing. This leads to, that on the surface of these “pockets” anodic coating is not formed. Hydrogen is also highlighted and the electrolytic coloring, whereby the portions can be formed with a pale color or no color.

Materials for anode hangers

Aluminium alloys

At the beginning of anodization of aluminum anodic sample produced exclusively from unalloyed aluminum, the lack of which is, that it is soft and easily damaged. This disadvantage has been eliminated, when steel is widely used thermally hardenable aluminum alloys, such, as 6061 и 2024. Used as a sample of available alloys 6060 и 6063, However, considered, that alloys 6061 и 2024 anodized slower, than other aluminum alloys, which provides the hinges with a longer service life [4].

Aluminum has the following advantages:

- Low initial cost

- It eases of machining

- High electrical conductivity

The main disadvantage of aluminum as a material for anode samples is:

- The need for alkali etching the anodic coating sample after anodization each cycle to restore the electrical conductivity of the surface. As a result, eventually weighed reduced thickness and requires replacement

Titanium alloys

Titanium (titanium alloys) have the following advantages:

- High durability and long service life

- Chemical inertness to most chemical solutions, besides chromic acid, chromate, hydrofluoric acid and fluorides

Disadvantages of titanium samples:

- High initial cost

- Require special equipment for repair

- A lower electrical conductivity, than aluminum

Electrical characteristics of aluminium and titanium

aluminum linkage, which are subject to immersion in electrolyte, You should have a cross-sectional area, which would provide at least, than 0,2 mm2/A [3]. Titanium linkage require a larger cross section, since titanium has a higher resistance to electric current, than aluminum. generally considered, that the electrical conductivity of titanium is only 10 % on the electrical conductivity of aluminum [1, 2].

Sources:

The making of aluminium cans

The making of aluminium cans- 11th Aluminium Two Thousand 2019