Bicycle frame aluminium: 6061 and 7005

Bicycle frame materials

Most bicycle frames made of

- steel

- aluminium alloys.

Less commonly and more expensively, bicycle frames are made from

- carbon fiber

- titanium alloys.

Bicycle frame quality factors

The quality of a bicycle frame is determined by four main factors:

- rigidity,

- strength,

- fatigue strength

- weight.

Bicycle frame aluminium alloys

Aluminum bike frames are mainly made from two aluminium alloys:

- 6061 aluminium alloy

- 7005 aluminium alloy.

- Some other aluminum alloys, for example, 7075 и 2014, stronger, than both alloys 6061 и 7005, but they are not enough suitable for the manufacture of bicycle frames, because they are almost impossible to weld, at least, usual argon-arc welding.

- It is often considered, that 6061 aluminium alloy is more suitable for bicycle frames, than an alloy 7005, although the alloy 7005 and somewhat more durable.

- The tensile strength of 7005-T6 alloy is 350 MPa, and 6061-T6 alloy is 310 MPa. Yield strengths are 290 and 275 MPa, respectively.

- In fact, under the load, which is generally subjected bicycle frame, differences between aluminum 6061 and 7005 alloys hardly ever, because stresses, that arise in the frame, sufficiently far from these limit values.

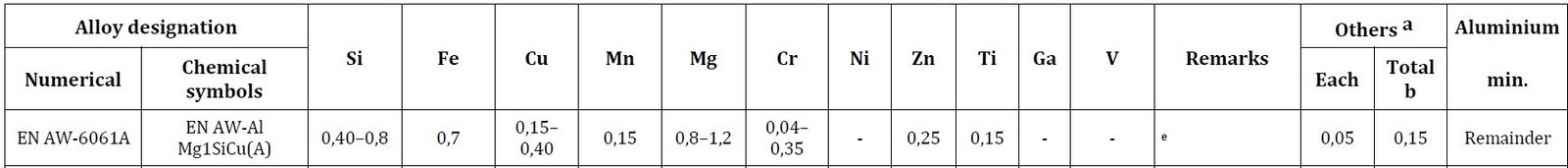

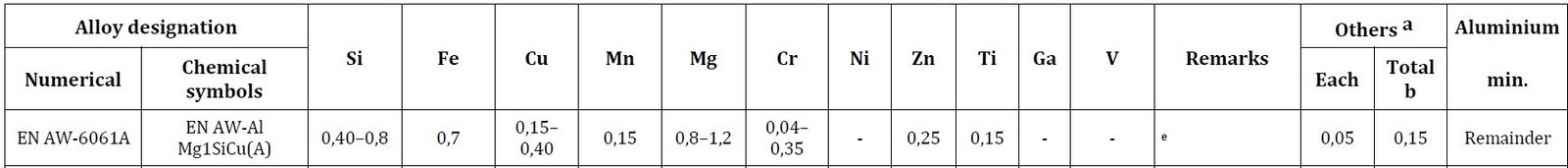

6061 aluminium alloy

Chemical composition

6061 aluminium alloy belongs to the 6xxx series of aluminum alloys (Al-Mg-Si).

The main alloying elements of 6061 aluminium alloy are:

- magnesium (0,8-1,2 %) and

- silicon (0,40-0,6 %),

- copper (0,15-0,40 %) and

- iron (up to 0,7 %).

Heat treatment after welding

6061 aluminium alloy has a relatively high strength, easily welded and is widely used not only for making bicycle frames, but also in construction, aircraft, shipbuilding.

Like all 6xxx series alloys, 6061 alloy is a thermally hardenable alloy. Heat treatment, which is applied to the already welded frames, includes:

- heating up 530 ° C

- intensive water cooling

- artificial aging at about 180 °C, 8 hours.

After such treatment 6061 aluminium alloy has the designation “6061-T6”.

Figure 1 – Chemical composition of 6061 aluminium alloy according to EN 575-3.

Figure 1 – Chemical composition of 6061 aluminium alloy according to EN 575-3.

A fragment of the table 6 from the EN 753-3 standard

Mechanical properties

Figure 2 – Mechanical properties for 6061 alloy extruded tubes in T6 temper.

Figure 2 – Mechanical properties for 6061 alloy extruded tubes in T6 temper.

(The fragment of Table 41 from the EN 755-2)

7005 aluminium alloy

Chemical composition

Aluminium alloy 7005 belongs to a series of 7xxx aluminum alloys without copper alloying (Al-Zn-Mg). Main alloying elements:

- zinc (approx 4,5 %) and

- magnesium (about 1,4 %).

Aluminium alloy 7005, as Alloy 6061, It is thermally hardenable. However, Unlike alloy 6061:

- for alloy hardening 7005 enough air cooling.

Figure 3 – Chemical composition of 7005 aluminium alloy according to EN 575-3.

Figure 3 – Chemical composition of 7005 aluminium alloy according to EN 575-3.

(The fragment of Table 7 from the EN 753-3)

Figure 4 – Mecanical properties for 7005 alloy extruded tubes.

Figure 4 – Mecanical properties for 7005 alloy extruded tubes.

(The fragment of Table 54 from the EN 755-2)

Heat treatment after welding

Alloy 7005 have ability to age-harden in the heat-affected zone up to about 80 % of the parent metal by natural aging and can be recover 100 % of strength if artifically aged after welding

Branded bicycle frame aluminium alloys

Aluxx, Aluxx SL and Aluxx SLR

The well-known bicycle company Giant apply their, branded aluminum alloy “Aluxx”. At the same time, the usual “Aluxx” – it’s just an aluminum alloy 6061, but with special designs “butted”, hydroforming technology, and heat treatment.

- Butting – thickening of pipes in critical sections, often at the ends of pipes.

- Hydroforming – forming pipes by placing them in special dies and pumping water or special oil under high pressure into them.

More advanced brands Aluxx SL and Aluxx SLR use aluminum alloy 6011, which is different from the alloy 6061 a slightly larger copper.

Figure 5 – Chemical composition of 6011 aluminium alloy according to EN 575-3.

Figure 5 – Chemical composition of 6011 aluminium alloy according to EN 575-3.

(The fragment of Table 6)

Alpha White, Black and Red aluminium alloys

Trek Company uses brands:

- Alpha White Aluminum and Alpha Black Aluminum are the usual 6061 alloy

- Alpha Red Aluminum is the thermally hardened 7075 aluminium alloy.

Figure 6 – Chemical composition of 6011 aluminium alloy according to EN 575-3.

Figure 6 – Chemical composition of 6011 aluminium alloy according to EN 575-3.

(The fragment of Table 6)

Figure 7 – Chemical composition of 7075 aluminium alloy according to EN 575-3.

Figure 7 – Chemical composition of 7075 aluminium alloy according to EN 575-3.

(The fragment of Table 7 )

Figure 8 – Mecanical properties for 7005 alloy extruded tubes.

Figure 8 – Mecanical properties for 7005 alloy extruded tubes.

(The fragment of Table 61)

Sources:

https://off.road.cc/content/feature/the-ultimate-guide-to-frame-materials-whats-best-for-bikes-664

https://www.bikeradar.com/advice/buyers-guides/bike-frame-materials/

https://www.giant-bicycles.com/global/aluxx-slr

https://www.bikeexchange.com.au/blog/bike-frame-materials-explained