Dummy block for aluminium extrusion

Dummy block

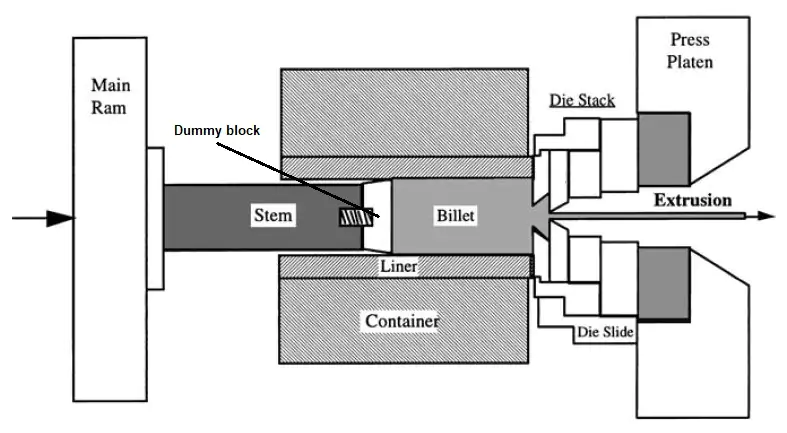

Dummy block is the most critical piece of extrusion equipment used in the aluminum extrusion process (Figure 1). Both the quality of the pressed product and the productivity of the press as a whole depend on it.

Figure 1 – A dummy block in the typical tooling configuration in diect extrusion process [1]

Figure 1 – A dummy block in the typical tooling configuration in diect extrusion process [1]

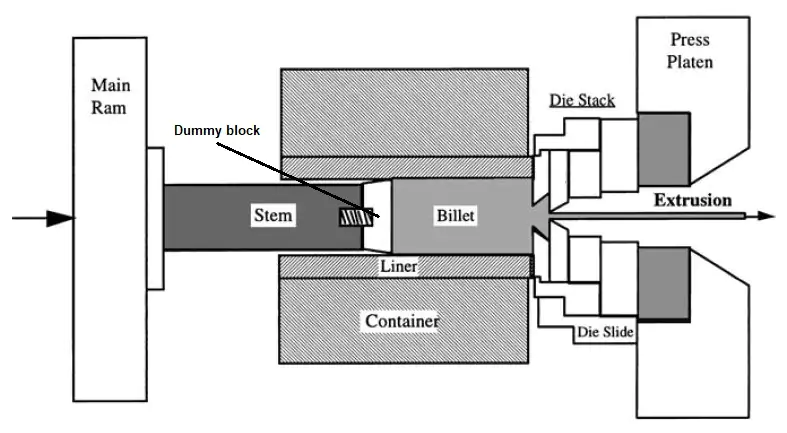

Figure 2 – Typical design of a dummy block.

Figure 2 – Typical design of a dummy block.

(a) Dummy block and coupling

(b) Stem and fixed dummy block [1].

(Source: Castool)

Good performance of dummy block

The good performance of the dummy block depends on many factors, for example:

- alignment of the press as a whole

- the temperature distribution of the container

- temperature and physical properties of the aluminum billet

- correct lubrication

- regular maintenance.

The functions of dummy block

The functions of the dummy block may seem very simple at first glance. This part, which is like a continuation of the press stem, is designed to directly push the aluminum alloy, softened by heating, through the die. The dummy block must perform the following functions:

- Transfer the press force to the alloy in each extrusion cycle under high temperature conditions

- Expand quickly to a predetermined limit under pressure (Fig. 3) and leave only a thin layer of aluminum alloy on the container sleeve

- Easy to separate from the billet after finishing its extruding

- Do not capture any gases. Trapped gas may cause damage to the container sleeve or the dummy block itself

- Help solve minor problems with press alignment

- Have the ability to quickly install/dismantle on the press stem.

- The dummy block must operate freely within the container to ensure maximum press performance.

- This must be ensured by good centering of the press. The deviation of the movement of the dummy block from the centering axis of the press is usually easily identified by uneven wear, which is visible on the ring of the dummy block. Therefore, the alignment of the press must be done regularly and carefully.

Figure 3 – Radial displacement of dummy pad under the press extrusion force [5]

Figure 3 – Radial displacement of dummy pad under the press extrusion force [5]

Steel for dummy block

Dummy block is the part of the extrusion tool that is subjected to high pressure. Dummy blocks are made of tool die steel, H13 steel according to the American classification. Before starting the press, the dummy block is heated to a temperature of at least 300 ºС. This increases the steel’s resistance to thermal stress and prevents cracking due to thermal shock.

Figure 4 – Damatool’s dummy block from H13 steel [2]

Figure 4 – Damatool’s dummy block from H13 steel [2]

Temperatures of billets, container and die

- An excessively heated billet (above 500ºC) will reduce the pressure on the dummy block during extrusion. This can lead to insufficient expansion of the dummy block and, as a result, extrusion of billet metal into the gap between the dummy block and the container. This can reduce the service life of the dummy block and even lead to significant plastic deformation of its metal.

- Similar cases may occur with containers that have different heating zones.

- The sticking of the dummy block to the billet is a really serious problem. This happens especially often on long bilets and soft alloys. A modern method of combating this is to apply a lubricant based on boron nitride to the end of the workpiece.

Maintenance of dummy block

Dummy block must be inspected every day:

- Possible aluminum adhesion is determined by visual inspection.

- Check the free movement of the rod and ring, as well as the reliability of fixation of all screws

- Every week dummy block must be removed from the press and cleaned in a die etching bath.

- During operation of dummy block, excessive expansion may occur. It is necessary to control that this expansion is not too large. Excessively increasing the diameter of the press washer can significantly reduce its service life

Sources:

1. Saha P. K. Aluminium Extrusion Technology, ASM International, 2000

2. http://www.damatool.com/en/urunler/9-dummy-block.html

3. https://www.pressmanual.online/wp-content/uploads/2023/05/3-tooling-2022a.pdf

4. https://www.castool.com/extrusion/dummy-blocks/

5. https://www.castool.com/wp-content/uploads/2023/09/Dummy-block-.pdf

Machinability of aluminium alloys

Machinability of aluminium alloys- Powder coating of aluminium products