Extrusion dies heating ovens

Why preheat dies?

Extrusion dies and support tooling must be preheated to a suitable temperature before being used in the press. This is necessary in order:

- to avoid breaking the die and

- to minimize the time needed to reach steady-state extrusion conditions [1-3].

The temperature of the extrusion tool is one of the critical parameters that must be tightly controlled to achieve consistency and repeatability in aluminum extrusion. Therefore, good die heating ovens are essential equipment for any extrusion press[1].

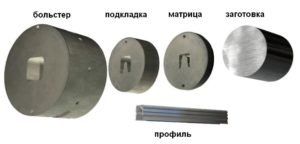

Figure 1 – Extrusion tools [1]

Extrusion dies and other extrusion tools are manufactured with high precision from heat-resistant tool steel using fairly complex technology. They are therefore quite expensive and must be handled carefully to ensure they last as long as possible. In addition, if the die is too cold or too hot, this can cause the press to run unproductively and produce excessive waste.

Types of die heaters

The most widely used are traditional chamber ovens with a hinged top lid. They take up little space and can be installed as close to the press as possible. Another common type of stove is the single oven. They are especially convenient to use for large-sized dies. These ovens require additional production space.

Less commonly, mainly in special industries, other oven designs are used:

- retractable

- rotary

- with an inert atmosphere

- induction

- infrared.

Top-loading ovens

The most common type of furnaces for heating matrices are furnaces in the form of a rectangular chamber with a hinged lid in the upper part (Figure 2). This type of stove is the cheapest, easiest to install and takes up the least amount of space.

Рисунок 2 – Камерные многоместные печи нагрева матриц производства компании Tecalex [3]

In each furnace, from 10 to 20 dies are simultaneously heated, depending on their size.

To provide faster heating and increase temperature uniformity, these ovens typically circulate hot air. In this case, direct radiation from the heat source to the instrument is prevented using special screens.

When working with these ovens, it is necessary to ensure that the newly loaded cold die does not take away too much heat from neighboring dies [2].

Single ovens

An improvement on chamber oven are single-place ovens. Several of these ovens are lined up in a workshop near the press. Each of them is designed to heat only one die. Due to the small size of the heating chambers, heating is carried out without the use of air circulation.

These ovens have the following advantages:

- The oven does not open to load and unload other extrusion tools

- There is never a cold die next to a heated die

- Heating the die takes less time

- Prevents overheating of the dies by making it easier to control the heating duration of each die.

Figure 3 – Single die preheat oven (Tecalex)

Ovens with drawer sections

These ovens have 3-5 sliding sections, each of which holds 4 or 5 dies. Each section has its own temperature control. Loading and unloading of one matrix set has less impact on other dies than with traditional chamber furnaces.

Figure 4 – Driver-type die heater [2]

Rotary die preheat ovens

Ovens of this type have a rotary table that can be rotated so that the desired matrix is opposite the loading and unloading window. This design is more expensive and requires more space. However, it provides increased die temperature uniformity because loading and unloading a die does not affect the temperature of other dies.

Figure 5 – Rotary oven for preheating matrices [2]

Figure 5 – Rotary oven for preheating matrices [2]

Ovens with inert atmosphere

Ovens with an inert atmosphere of argon or nitrogen are gaining popularity to reduce the oxidation of dies. Each die is housed in a separate drawer, providing very precise temperature control, reducing heating time and saving energy. These ovens require increased control and maintenance costs.

Figure 6 – Inert atmosphere-type die heater [2]

Heating methods

Gas oven

With direct gas heating, it is more difficult to control the temperature, and gas combustion products, including water vapor, can adversely affect the matrix metal. Therefore, if necessary, only indirect (indirect) gas heating is used using radiant tubes.

Electric resistance heaters

Most matrix heating furnaces use electric resistance heaters. These heating elements are reliable and well regulated to ensure uniform temperatures. Electrical elements must be located in the furnace so as not to create local overheating of the matrix metal.

Induction electric heating

These ovens can heat the dies to operating temperature in a few minutes. Since heating occurs inside the matrix, holding at temperature is not required. An important advantage is the absence of harmful long-term exposure of matrices to high temperatures – longer service life, less oxidation and damage to working belts. However, these ovens have a high initial cost and high maintenance costs.

Infrared heating

These furnaces use infrared radiation to heat the matrices. Suppliers of these furnaces claim that these furnaces provide fast and accurate heating of the dies.

Rules for heating extrusion tools

What is unproper heating dies?

When used correctly, the die heating furnace should heat the pressing tool to the desired temperature, regardless of where in the furnace it is located. The duration of stay of matrices and other tools in the furnace must be strictly regulated [1]:

- If heated for insufficiently long time, the die may break during extruding on the press.

- If heated for excessively long time, the die may lose its hardness. The bearings of the die will become heavily oxidized.

It is known that many aluminum extruders do not preheat the auxiliary pressing tools (pads, subbolsters and bolsters) at all [1]. However, experts categorically recommend heating not only the dies themselves, but the entire pressing tool supporting them. Each time a new die is installed, cold pads, sub-bolsters and bolsters rob the die of heat and prolong the process of stabilizing the extrusion process.

Heating temperatures for extrusion tools

Solid dies

- The heating temperature of the die is determined experimentally for each die.

- In the absence of experimental data, a temperature of 425 to 455 ºC is recommended.

- Dies with critical “tongues” need to be heated to a higher temperature.

Hollow porthole and spider dies

- are heated to temperatures from 455 to 510 ºС.

Bridge dies

- are heated to a temperature 55-110 ºС below the temperature of the billet, depending on the extrusion ratio and the profile shape

Solid die bolsters

- must be heated to the same temperature as the die and backer, or to a temperature of at least 200ºC.

Hollow die bolsters

- should be heated to the same temperature as the hollow die assembly. In this case, the bolster must be transferred to the press in a minimum time in order to maintain the temperature required for extrusion.

Once the specified surface temperature has been reached, the tool must be kept in the oven for 45 minutes per 25 mm of total thickness to achieve temperature uniformity in the air-circulating oven.

Temperature difference in the die heating oven

The temperature difference across the die heating furnace should be no more than 15 ºС. “Hot” and “cold” spots in the oven are eliminated by installing additional heat shields to change the flow of circulated air.

Oven Temperature Accuracy

- The accuracy of the actual temperature in the furnace is monitored at least once a month by comparison with a control thermocouple and recording the readings.

- It is recommended to have two temperature measuring instruments on the oven in case one of them fails.

Sources:

- Aluminum Extrusions From Start to Finish – Presentation / Randy Thomure, Sapa Extrusions, 2013.

- Die Ovens / Extrusion Press Maintenance Manual / Al Kennedy.

- Die Ovens – Castool

Aluminium Two Thousand 2017 Congress

Aluminium Two Thousand 2017 Congress- Methods of aluminium brazing