Production of recycled aluminium

Production of recycled aluminium

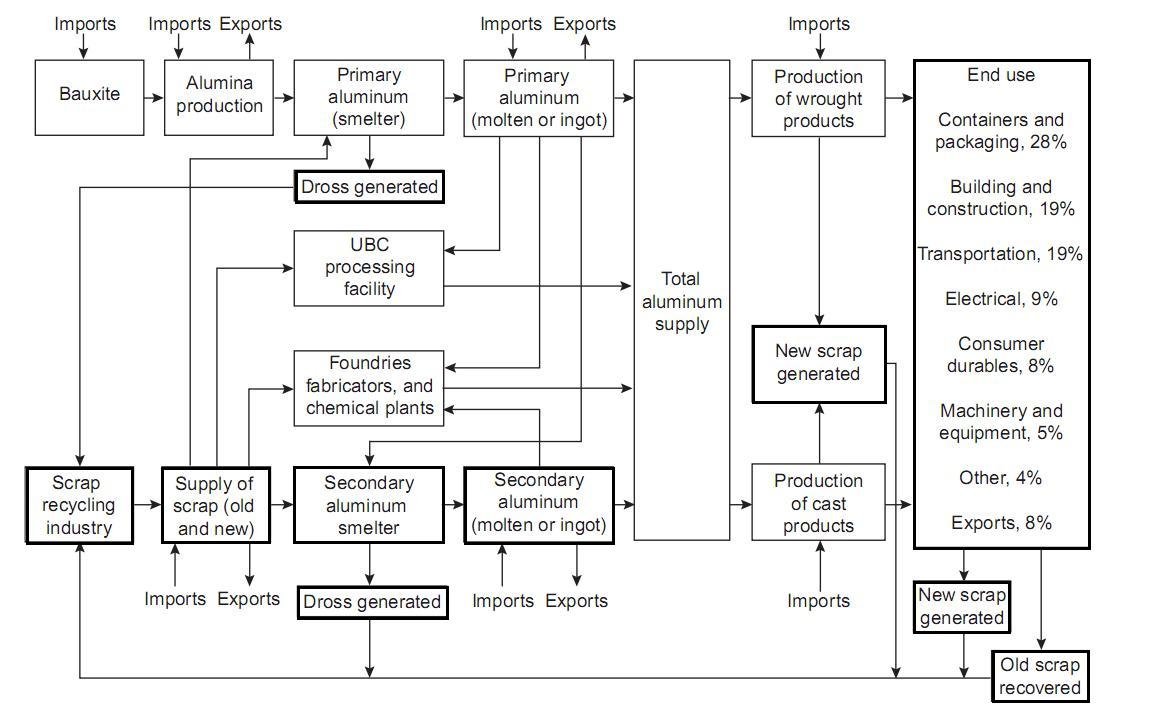

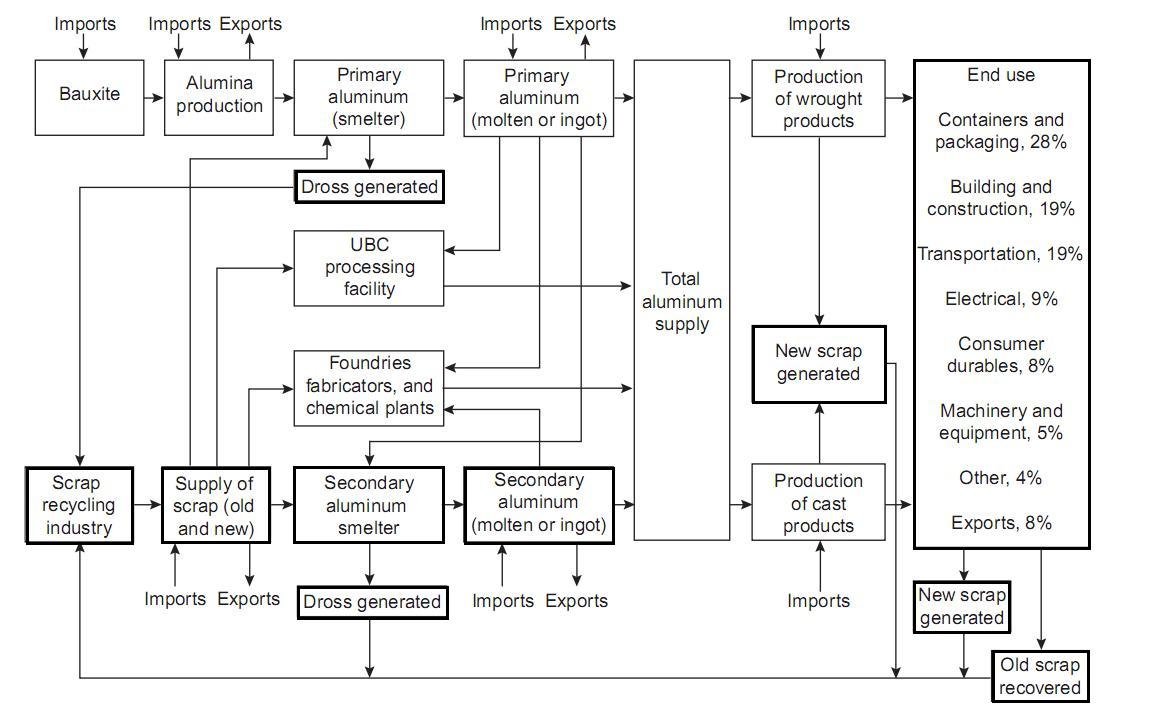

Recycling aluminum scrap is a complex interactive process, which includes centers for the collection and processing of scrap, primary aluminium producers, secondary aluminum producers, metal processing industries and consumers of aluminum products. Figure 1 shows material flows in the aluminium industry, starting from primary aluminium producers and through various production facilities for the processing and remelting of aluminium scrap. The figure 2 presents a model of the structure of the global production of recycled aluminium, which shows the material flows of various types of aluminium scrap and the main types of equipment used [2].

Figure 1 – Material flows in the global aluminum industry:

Figure 1 – Material flows in the global aluminum industry:

the role of secondary aluminum [1]

Figure 2 – Material flows in production of recycled aluminium [2]

Remelters and refiners

Secondary aluminum from aluminum scrap is recovered by two types of industrial enterprises, which will be called below “remelters” и “refiners” [2, 7] (Fig. 3 and Fig. 4):

- Remelters:

– melted down a relatively large, pure and slightly oxidized aluminum scrap (figure 3);

– produce wrought alloys (content of alloying elements up to 10 %); - Refiners:

– remelted painted (figure 4), contaminated and highly oxidized aluminum scrap, including crushed (figure 5), shavings (figure 6) and slags (figure 7);

– produce casting alloys and aluminum for steel deoxidation; casting alloys have an alloying element content of up to 20 %.

Fig. 3 – Remelters and refiners in aluminium production [7]

Fig. 4 – Remelters and refiners in Europe [7]

Fig. 4 – Remelters and refiners in Europe [7]

Figure 5 – The role of remelters and refiners in the aluminum industry [7]

Figure 6 – Pure aluminium scrap [3]

Figure 7 – Painted aluminium scrap [3]

Figure 7 – Painted aluminium scrap [3]

Figure 8 – Shredded aluminum cans scrap [3]

Figure 8 – Shredded aluminum cans scrap [3]

Figure 9 – Aluminum scrap “turnings” [3]

Figure 9 – Aluminum scrap “turnings” [3]

Figure 10 – Aluminum dross

containing metallic aluminum 50-75 % [3]

Remelters must select the right amount and quality of aluminium scrap, to “get” into the chemical composition of a given deformable aluminium alloy. So they take action, to carefully separate different aluminum alloys.

Refiners work in less severe conditions in relation to various aluminium alloys. They specialize in the remelting of mixed casting and wrought alloys into standardized aluminium alloys.. It is common practice for refiners to proportionally mix different alloys in a batch, which is intended to be loaded into the furnace.

Aluminium scrap: purchased and internal

Recycled aluminium is produced from purchased and internal aluminum scrap. Scrap, which is formed and melted within the same company or group of companies is called internal scrap. With a few exceptions, refiners are separate small and medium-sized enterprises, and remelters are subdivisions of an enterprise or a group of enterprises, who produce any aluminium products. Therefore, only remelters produce secondary aluminium from internal scrap.

- New scrap is generated at the stages of aluminium production and the manufacture of semi-finished or finished products from it.

- Old scrap is formed, when an aluminium-containing product, reaches the end of its service life, goes to scrap, sorted and remelted.

Remelting aluminum scrap

It is known, that aluminium cannot be reduced from its oxide to metal with carbon or hydrogen near its melting point, how does this happen, for example, with iron. In this regard, in the production of primary aluminium, an energy-intensive electrolysis process has to be used., to recover metallic aluminium from aluminum oxide (Al2O3). Recycling of aluminium is limited to the remelting (smelting) of aluminium from aluminum-containing materials, which make up the aluminium scrap. This provides a simple method for calculating the mass balance in aluminium recycling (without taking into account the influence of alloying elements) [2]:

(metallic aluminium input) =

= (metallic aluminium output) + (oxidized metallic aluminium) /1,89

All oxides or other inorganic non-metallic components of the scrap remain unchanged during melting and, when calculating the mass balance, simply pass from input to output. Salts (fluxes) remain salts, which are needed mainly as an enveloping material for inorganic non-metallic components. Oxides either enter the furnace as part of the charge or are formed during the melting process. Volatile organic compounds (e.g., oils, grease) and moisture leave with flue gases, but may carry some components, such as salts or oxides [2].

Furnaces for remelters

Remelters use:

- mostly traditional melting furnaces bath type without the use of melting fluxes. These are usually reverberatory deck ovens of various types: front loading furnaces, shaft furnaces, ovens with inclined (dry) hearth, etc. (Figures 11-13).

Figure 11 – A reverberatory bath melting furnace with front loading [4]

Figure 11 – A reverberatory bath melting furnace with front loading [4]

Figure 12 – A shaft melting furnace [5]

Figure 12 – A shaft melting furnace [5]

Figure 13 – A melting furnace with inclined hearth and storage box [6]

Furnaces for refiners

Refiners use:

- bath-type furnaces without the use of a layer of melting fluxes with additional electromagnetic stirring, as well as with a side loading well (Figure 14);

- rotary furnaces with a stationary (fixed) axis of rotation (Figure 15);

- rotary furnaces with a tilting axis of rotation (tiltable rotary ovens) Figure 16);

- furnaces for processing salt slag, which give out recovered (secondary) fluxes and granular aluminum;

- equipment for processing wet shavings;

- other types of furnaces (in small quantities).

Figure 14 – A melting furnace with charging well [6]

Figure 14 – A melting furnace with charging well [6]

Figure 15 – A rotary melting furnace with fixed axis of rotation [6]

Figure 15 – A rotary melting furnace with fixed axis of rotation [6]

Figure 16 – A tilting rotary melting furnace [3]

Remelters: features of work

For remelters, the main characteristic is the quality of the charge:

- clean scrap, unoxidized and unpainted

- in most cases – scrap with one type of aluminum alloy.

The metal yield is very high, that is, the metal content is from 96 % to 100 %. Such scrap does not require melting fluxes, which are designed to envelop inorganic non-metallic components. A small amount of coating flux is required to protect against oxidation during slag formation. Remelters can use different types of furnaces, however, the most typical is a bath oven, gas and inclined hearth. Near 0,15 % the total amount of metal in the charge is converted into oxides. Hot slag, removed from the surface of the melt, contains about 70 % metal, mostly absorbed by slag. This slag is collected in a steel box., where it is covered with a layer of flux (up to 5 % from the volume of removed slag) to prevent oxidation of most of the slag. The final metal content in the cooled slag will be about 60 %. This slag is sent to refiners for processing., which remelt it under a layer of fluxes.

Refiners: features of work

The main types of ovens, who apply refiners, are:

- Rotary furnaces of various types for melting under a layer of oxidized flux, painted or contaminated scrap, as well as slag. Rotary kilns with fixed axis of rotation form ordinary liquid salt slag, which contains on average 50 % salt. Average oxidation of aluminum is 3 %. The metal content in the slag is 8,5 % at the time of its unloading. Tilting rotary kilns are more suitable for remelting slag..

Some refiners use hearth furnaces (often multi-chamber) for scrap with a high content of organic contaminants – for continuous melting of a homogeneous type of scrap. These furnace work without the layer of flux unlike rotary furnaces. They are usually equipped with an electromagnetic pump, which provides fast immersion in the melt, for example, dry aluminum shavings. This ensures the level of oxidation of the chips during melting no more than 0,2 %.

A common practice for refiners is to drain the metal from the smelting furnace using a chute into a special holding furnace., which is designed to process the melt and transfer the metal to casting machines or to a ladle for further transportation. In this furnace, the melt is degassed, adjusting the chemical composition of the alloy, settling and other treatments. The slag formed in this furnace is returned to the rotary furnace., with fixed axis of rotation or tilted.

Sources:

- Aluminum Recycling and Processing for Energy Conservation and Sustainability/ed. John A.S. Green – ASM International – 2007

- Melting Standardized Aluminum Scrap: A Mass Balance Model for Europe /U.M.J. Boin and M. Bertram – JOM, August 2005

- Aluminium Dross and Scrap Recycling – The Hybrid Tilting Rotary Furnace MASTERmax – www.kmf.at – 2021

- Handbook of Aluminium Recycling / Сh. Schmitz, 2014

- TALAT Lecture 3202 – The Liquid Metal / John Campbell and Richard A. Harding – 1994

- TALAT Lecture 1102 – Environmental Factors / Geoff Budd – 1994.

- Aluminium Recycling in Europe The Road to High Quality Products – EAA/OEA Recycling Division

Construction aluminium scrap

Construction aluminium scrap- Is aluminium a coin metal?